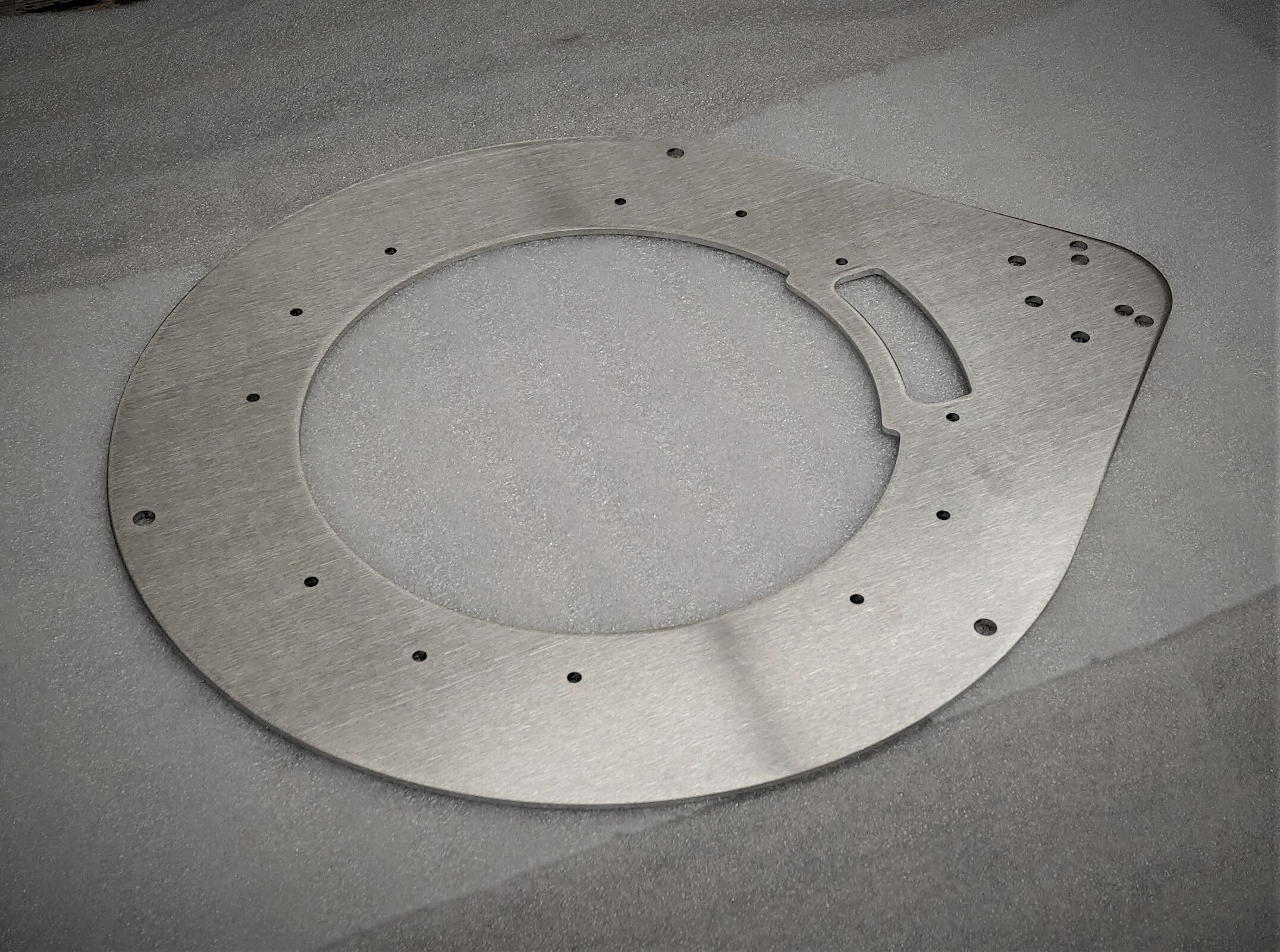

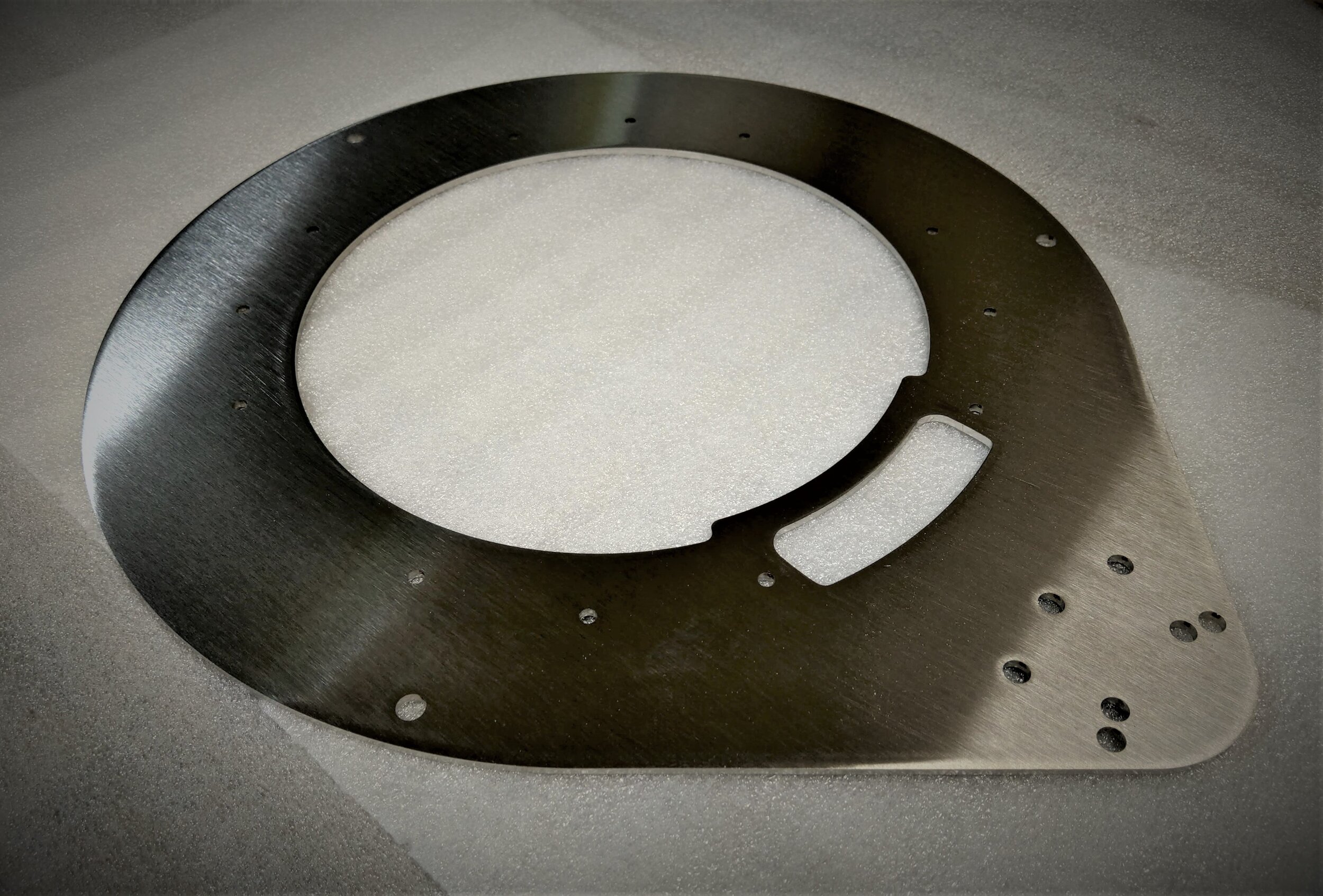

Laser Cutting

What we can cut

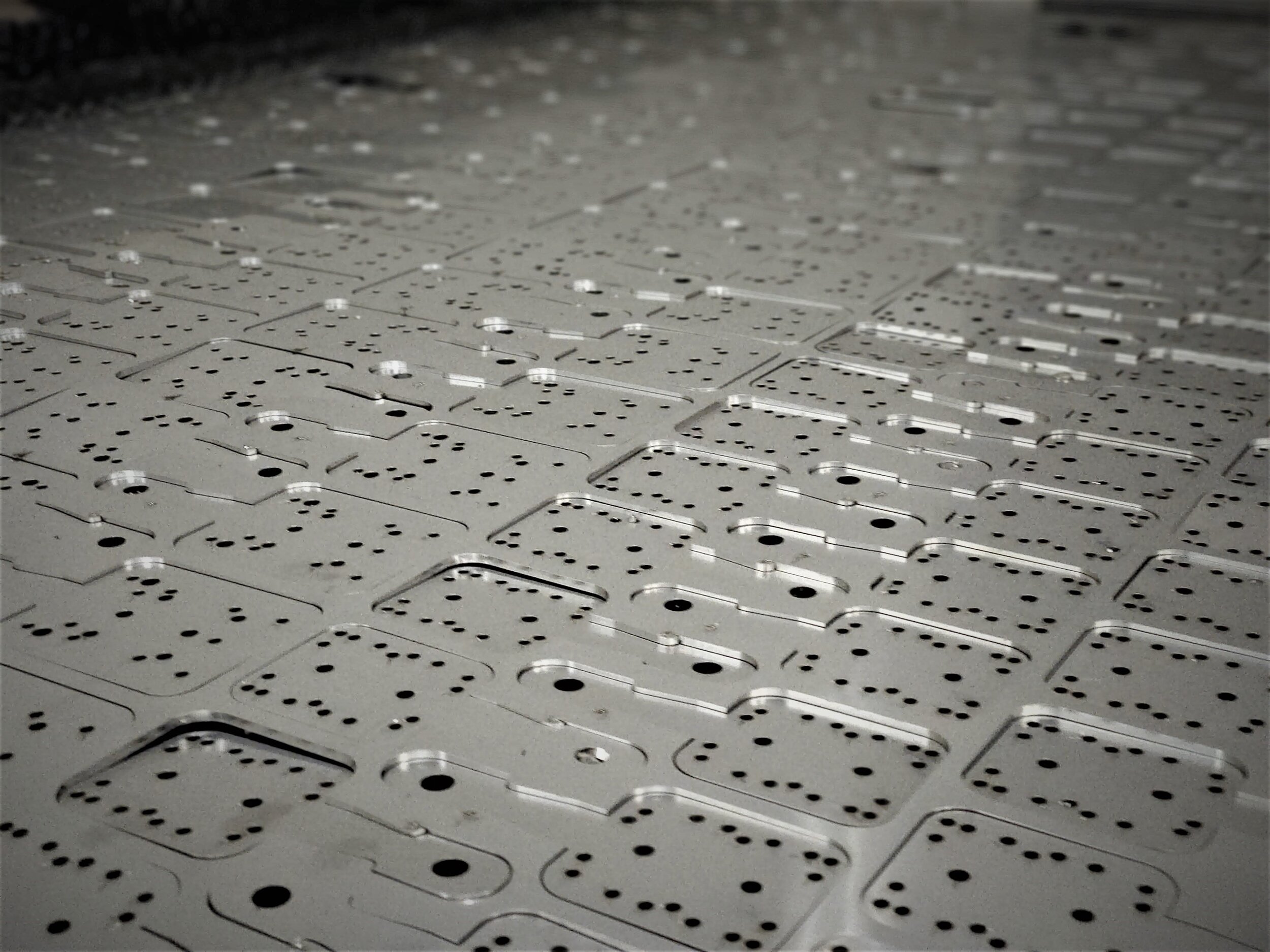

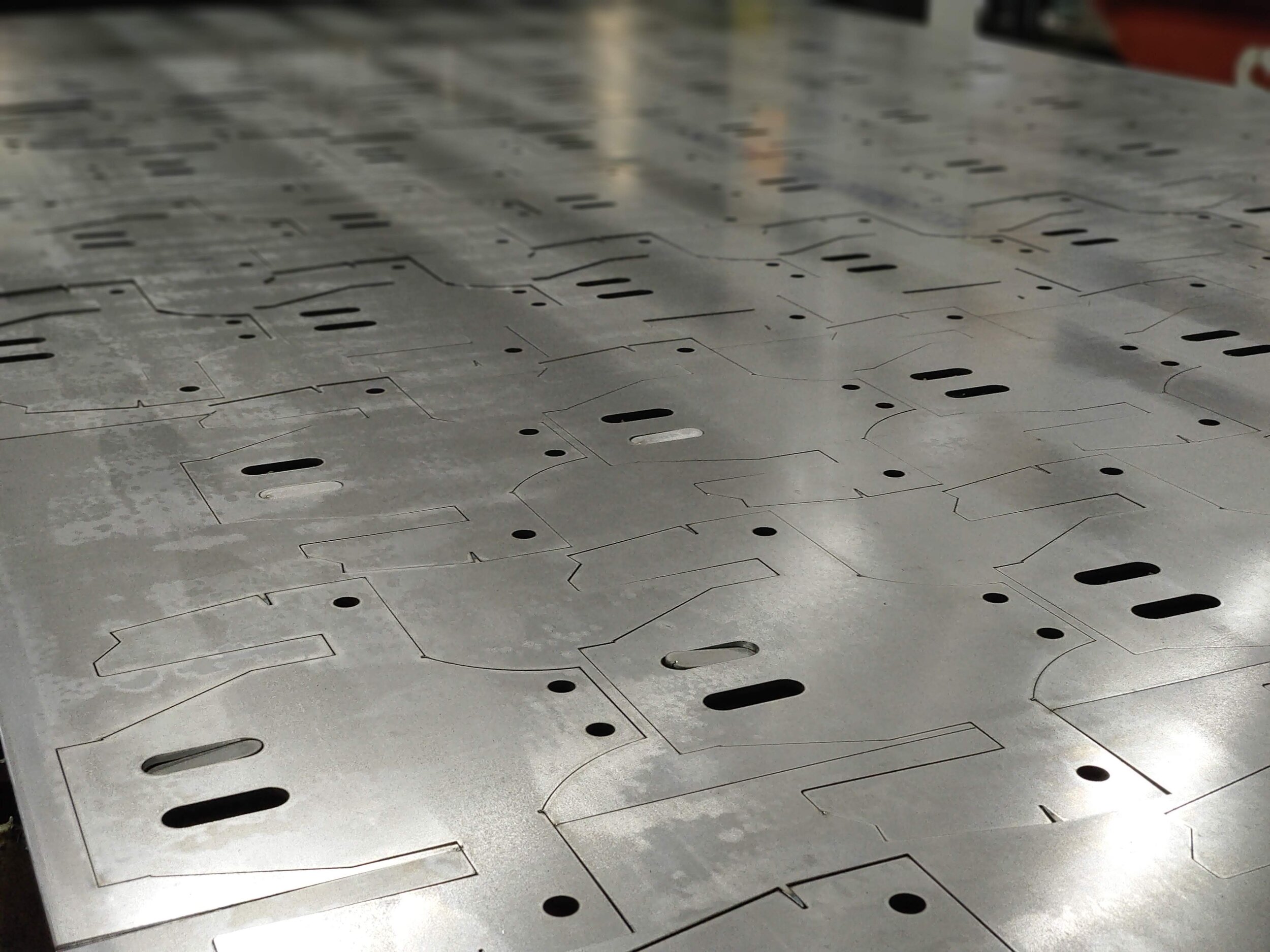

Here at First Metals, we use 2 Mitsubishi CO2 Cutting Lasers to meet most of our 2D cutting needs. These machines cut steel between .020” - 1.250” thick (including alloy steel, high carbon steel, and high-strength-low-alloy steel), stainless steel between .020” - .500” thick, and aluminum between .020” - .375” thick, as well as more special-case materials such as brass, bronze, titanium, polycarbonate, and more with excellent accuracy in both kerf and positioning. Both machines have work-tables measuring 5 feet wide by 10 feet long, and each machine has its own 2 independent work tables to eliminate delays between jobs.

Capable

Carbon Steel

High Strength Low Alloy Steel

High Carbon Steel

Alloy Steel

Galvanized Steel

Aluminum

Stainless Steel

Special Case

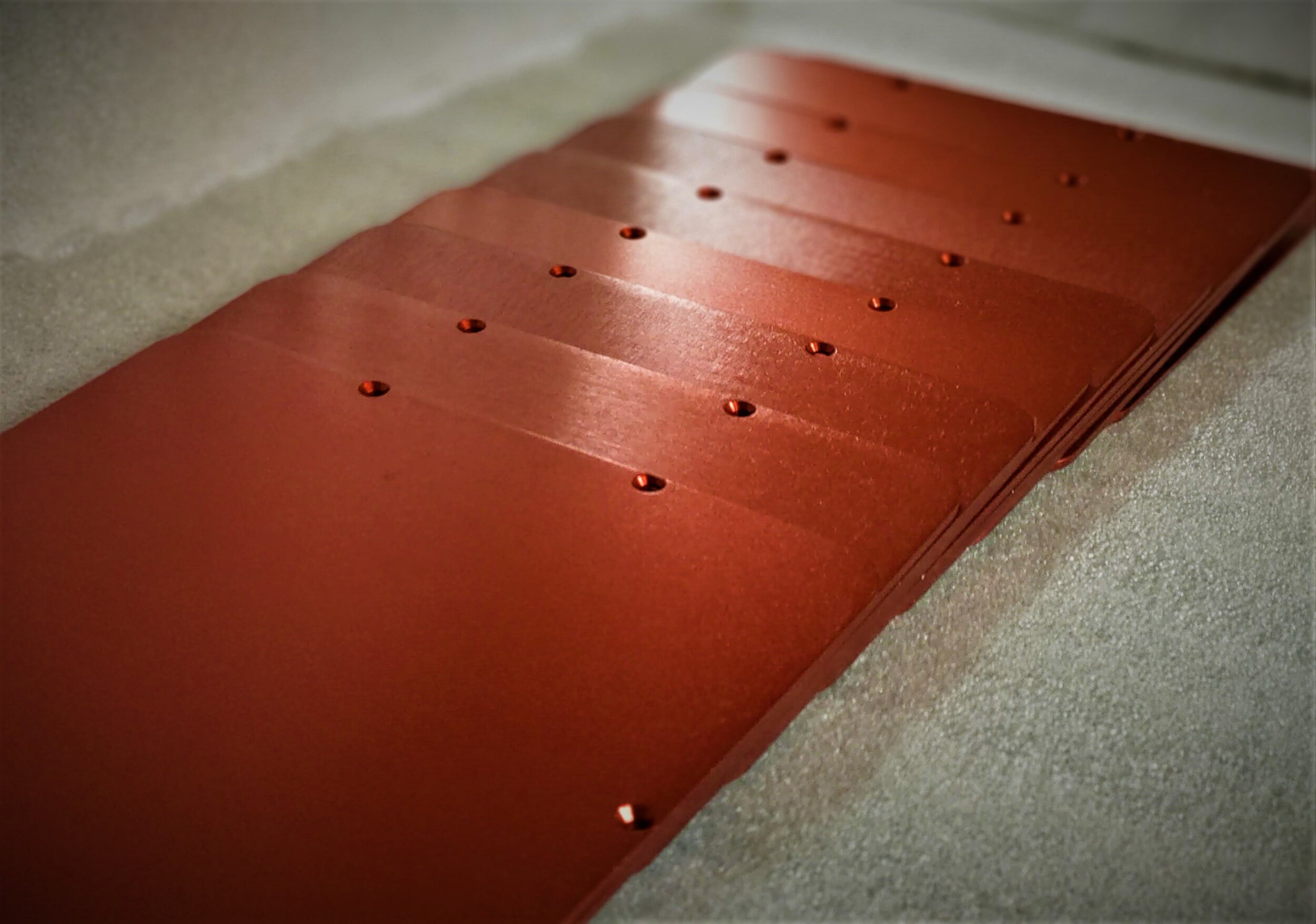

Copper

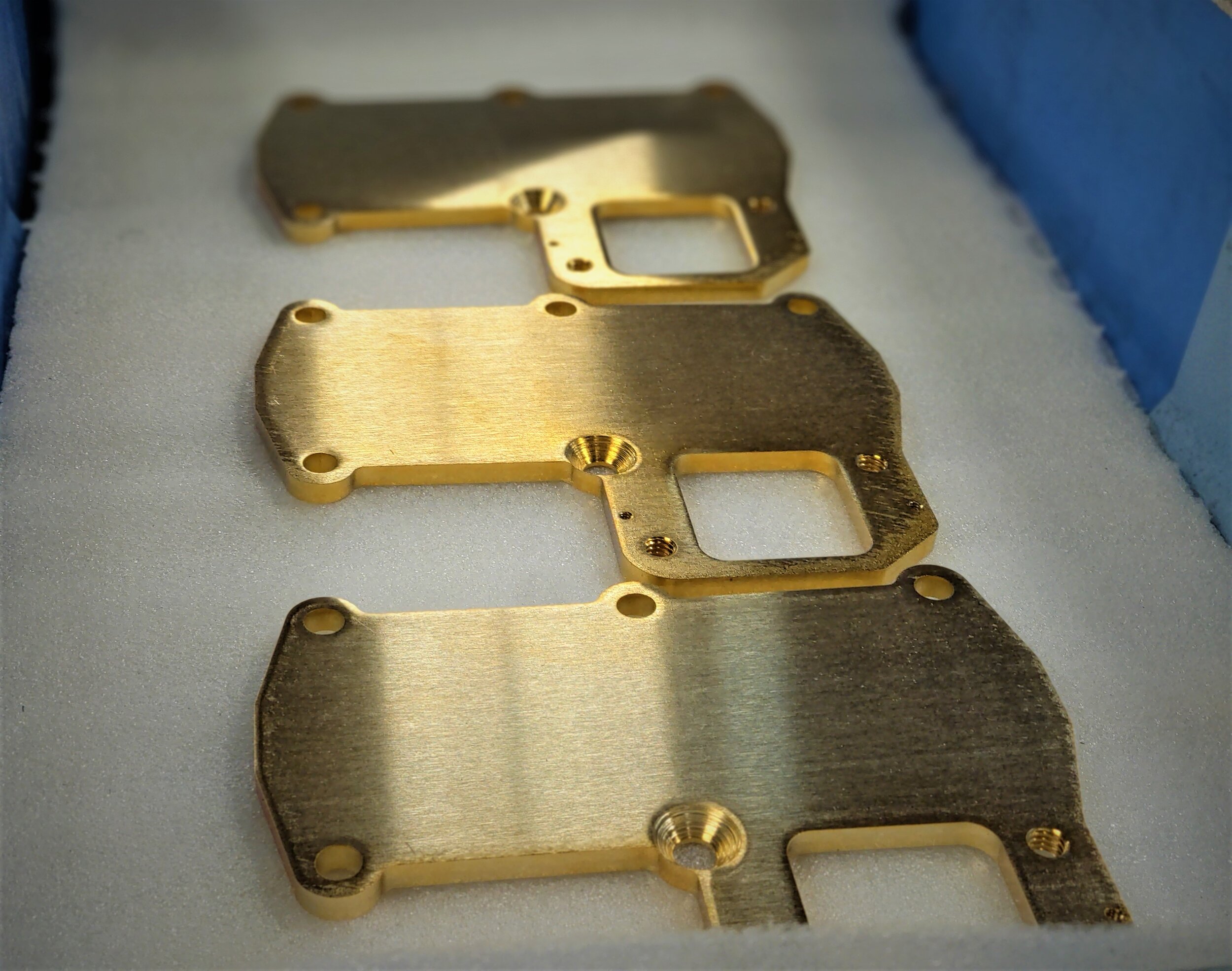

Brass

Bronze

Titanium Alloys

Nickel Alloys

Acrylics

Polycarbonate

Wood

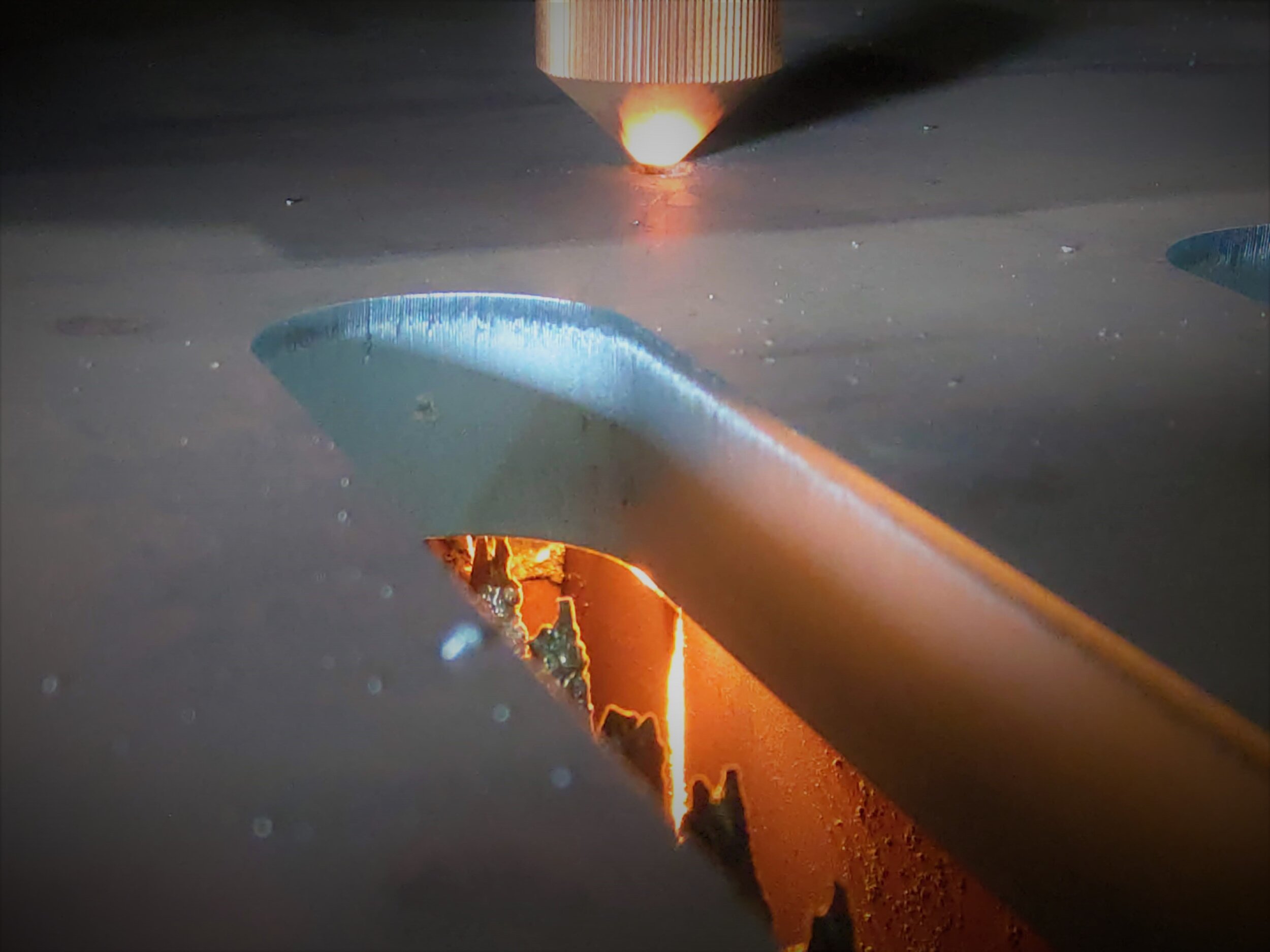

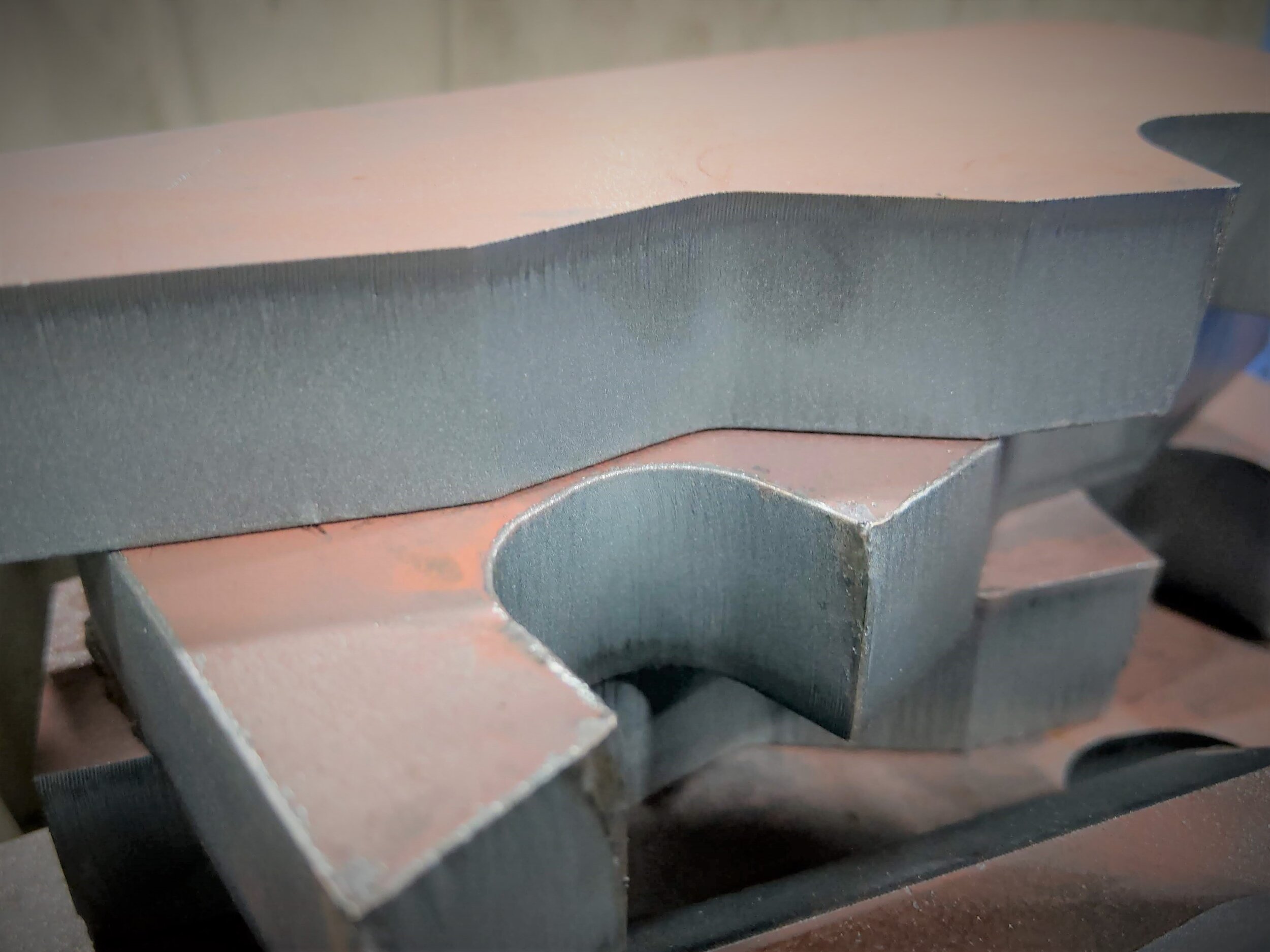

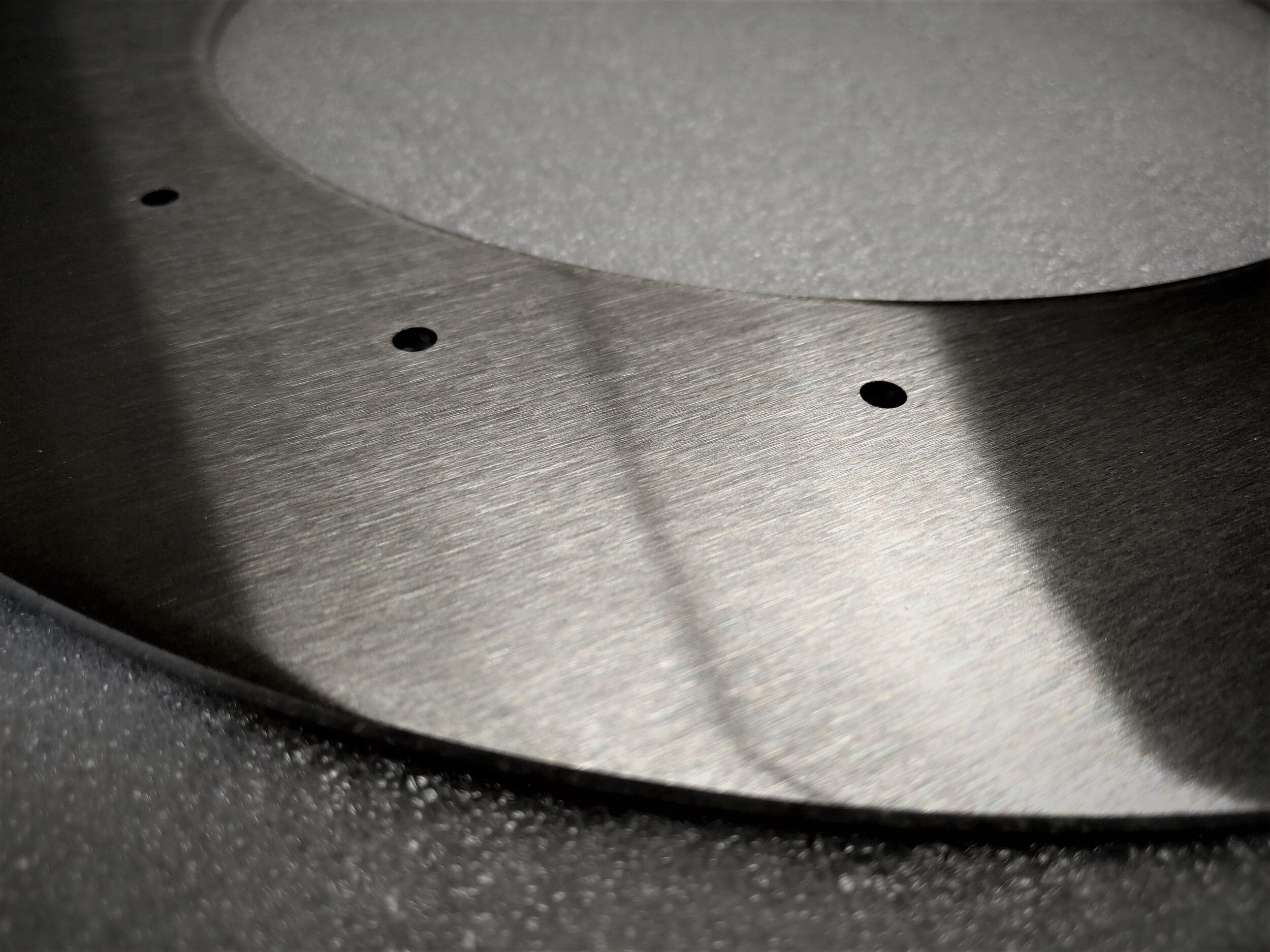

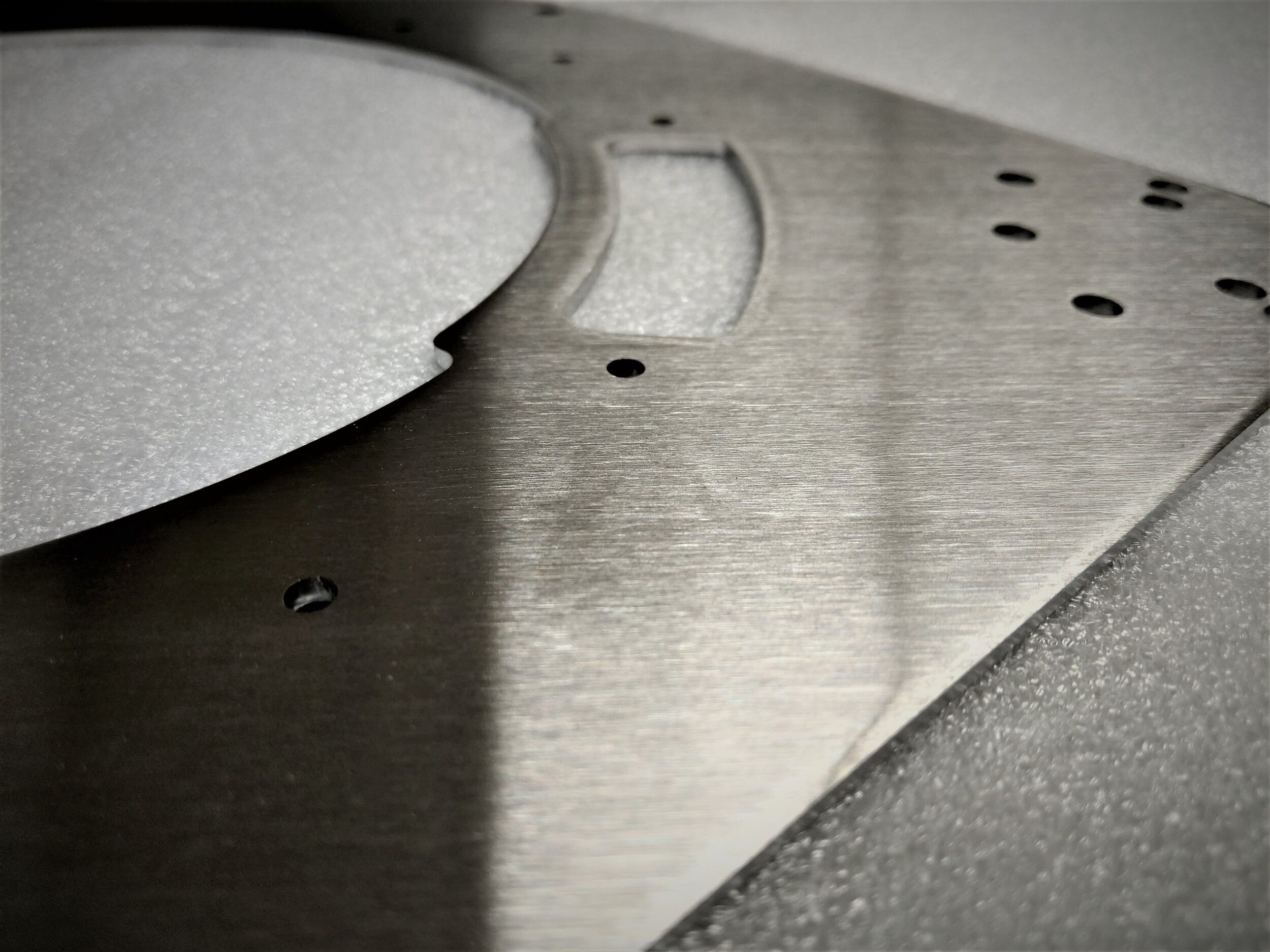

Cut Quality

We can hold tolerances of +/-.0015” on .250” thick steel plate with our machines, growing to +/-.020” on 1.0” steel plate. Striations will become visible on laser-cut edges in all parts from all materials above .250” thick, and aluminum above .060” thick. The cut surface is kept as consistent as possible with peak and valley deviations at a minimum. We can eliminate scale on laser cut edges for parts that get a powder coat application. Our cutting lasers can also support simple etching and engraving for applications which do not require a lot of detail (i.e. weld locations for use during assembly, bend line indicators on very large parts, simple part numbers, etc.). For applications which do require a lot of detail, we have a dedicated marking laser.

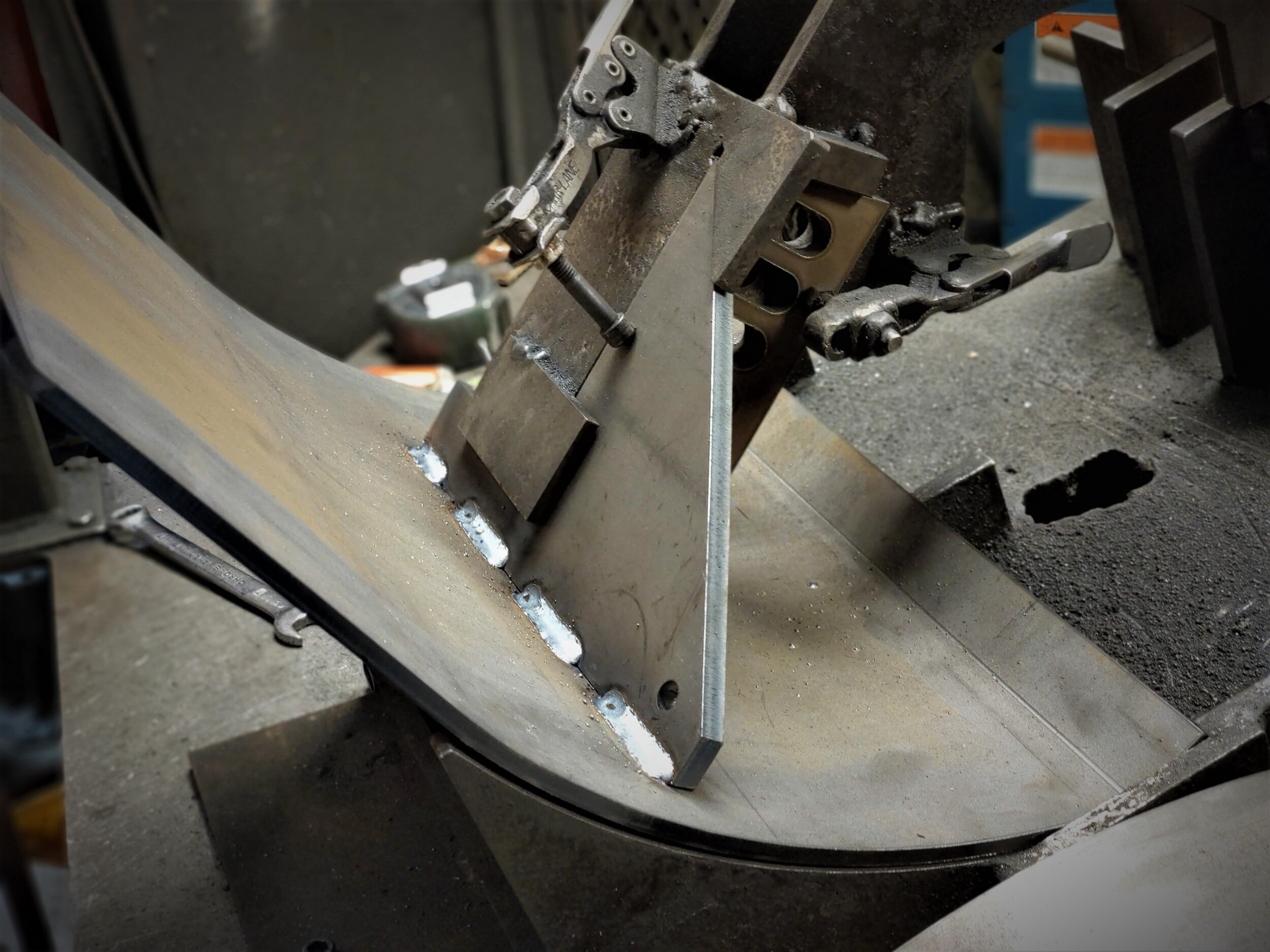

FORMING

Performance range

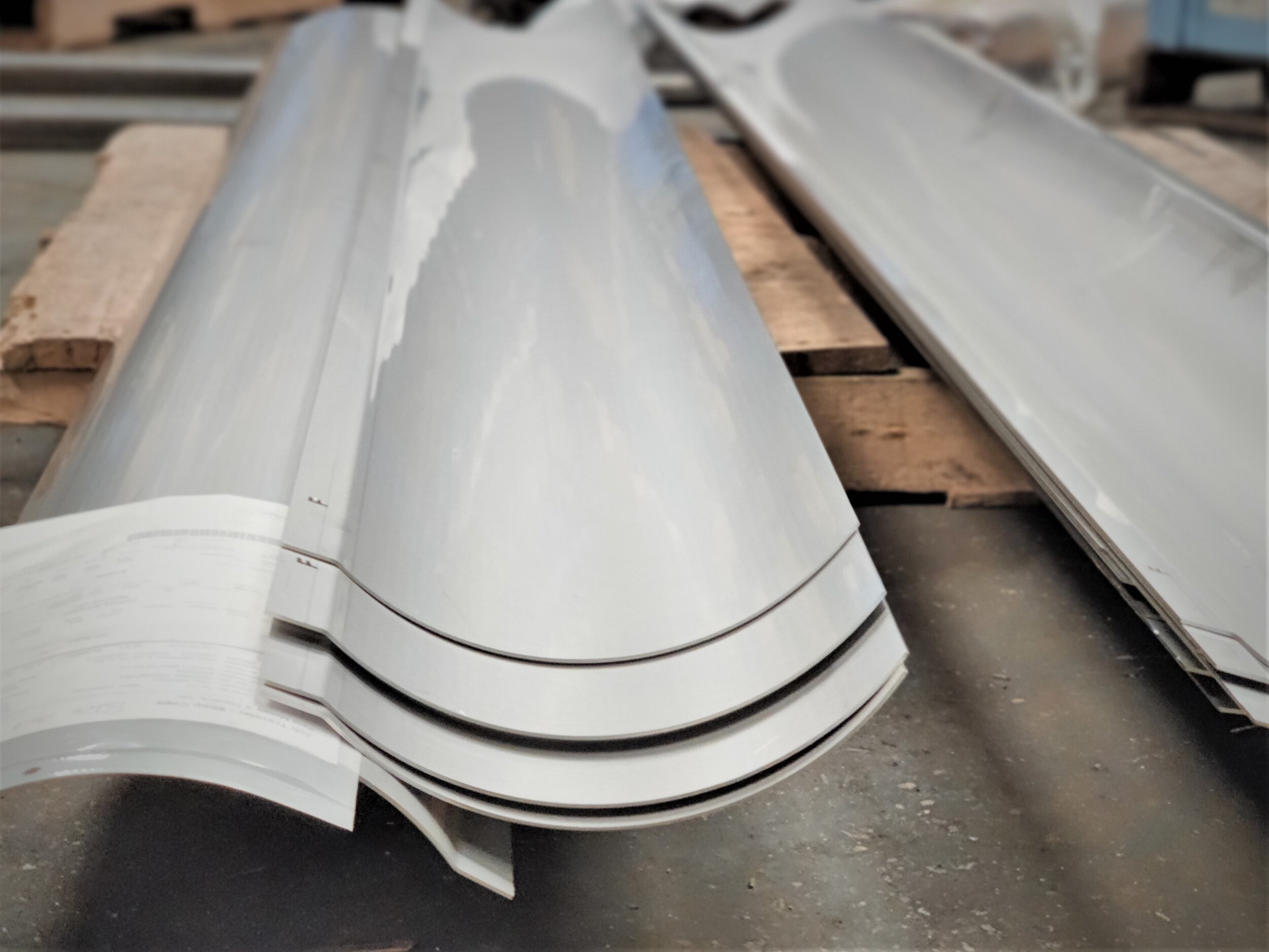

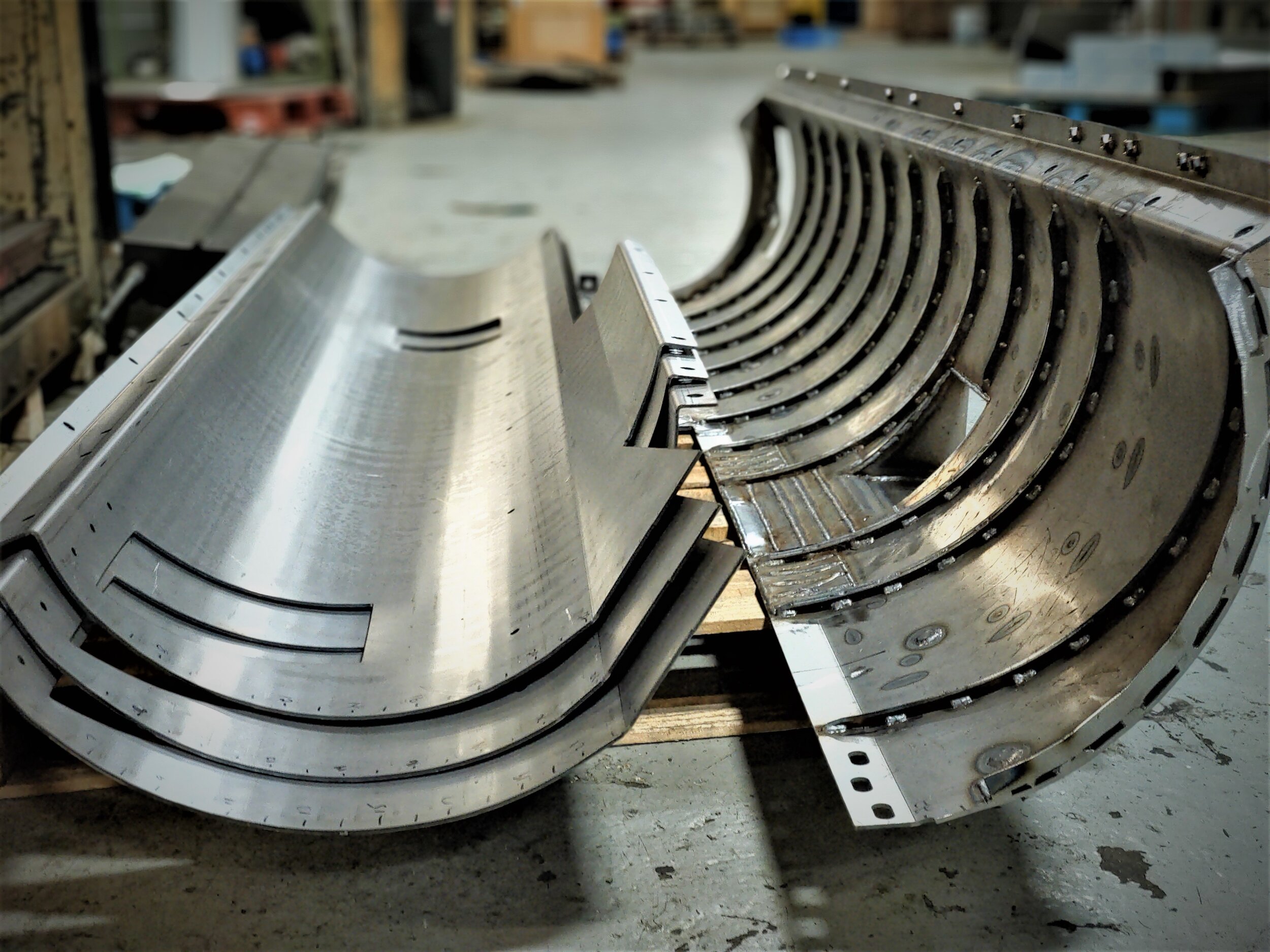

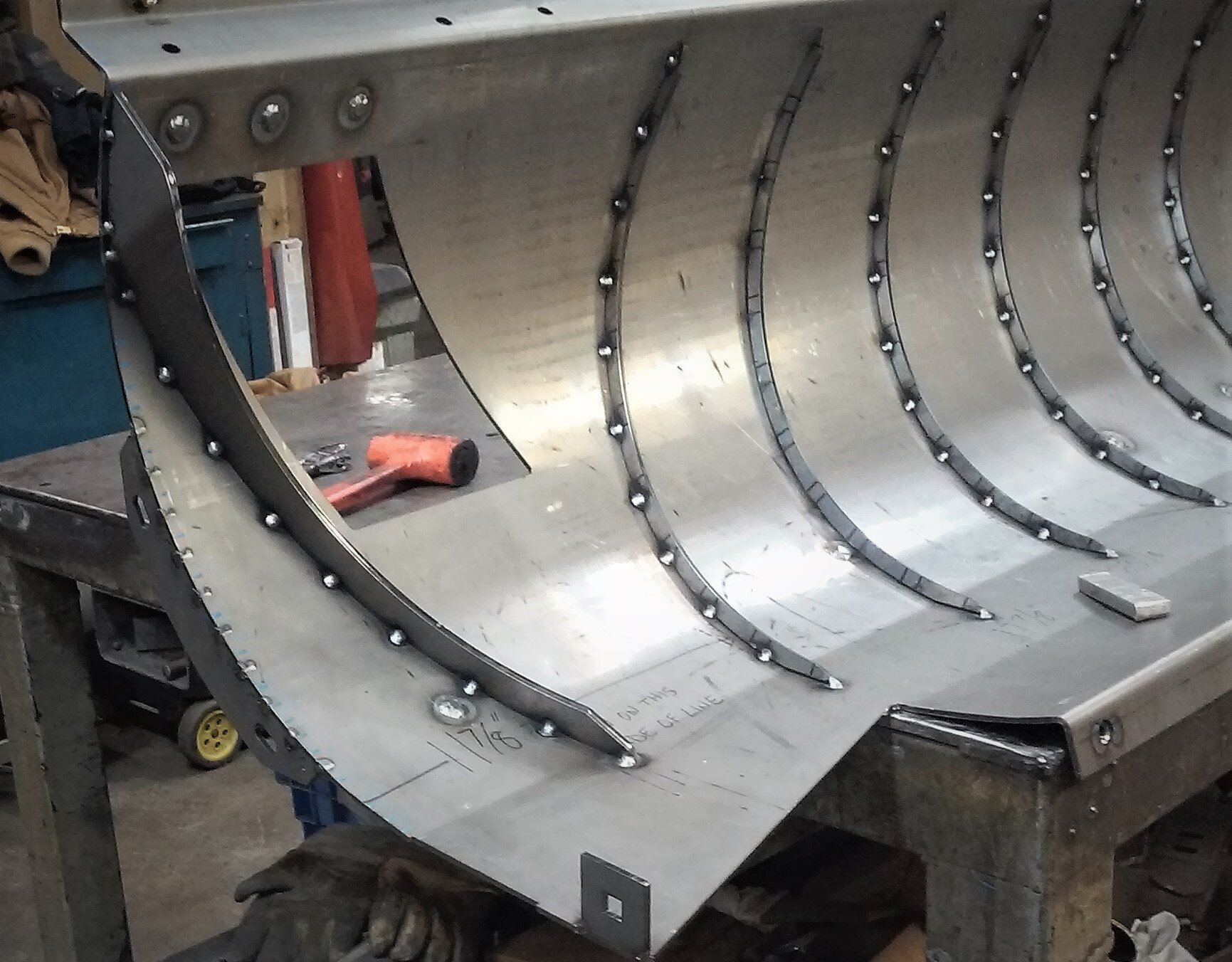

We have multiple press brake machines with varying tonnages and work-lengths up to fourteen feet. With a wide range of tooling available, including the option to make custom tooling, we can meet all of your needs for bending, folding, and forming steel, stainless steel, and aluminum on one or more of our presses.

Having versatility in work lengths and tonnage for press braking parts, we are capable of forming larger parts from thicker and stronger materials. With a full machine shop, laser cutters, and welding capabilities, we are well-practiced in the making of our own custom tooling for our press brakes, leaving us undaunted by even very complex patterns.

New Amada

Our newest press is a 143 ton Amada with a 122 inch work length and a ram repeatability of +/-.00004 inches. Purchased new in 2019, this press is the latest flagship model from Amada, armed with a full array of quick change tooling, a multi-axis back-gauge, and an automated robotic bend angle sensor. This press brings best-in-class multi-stage bending capabilities to First Metals.

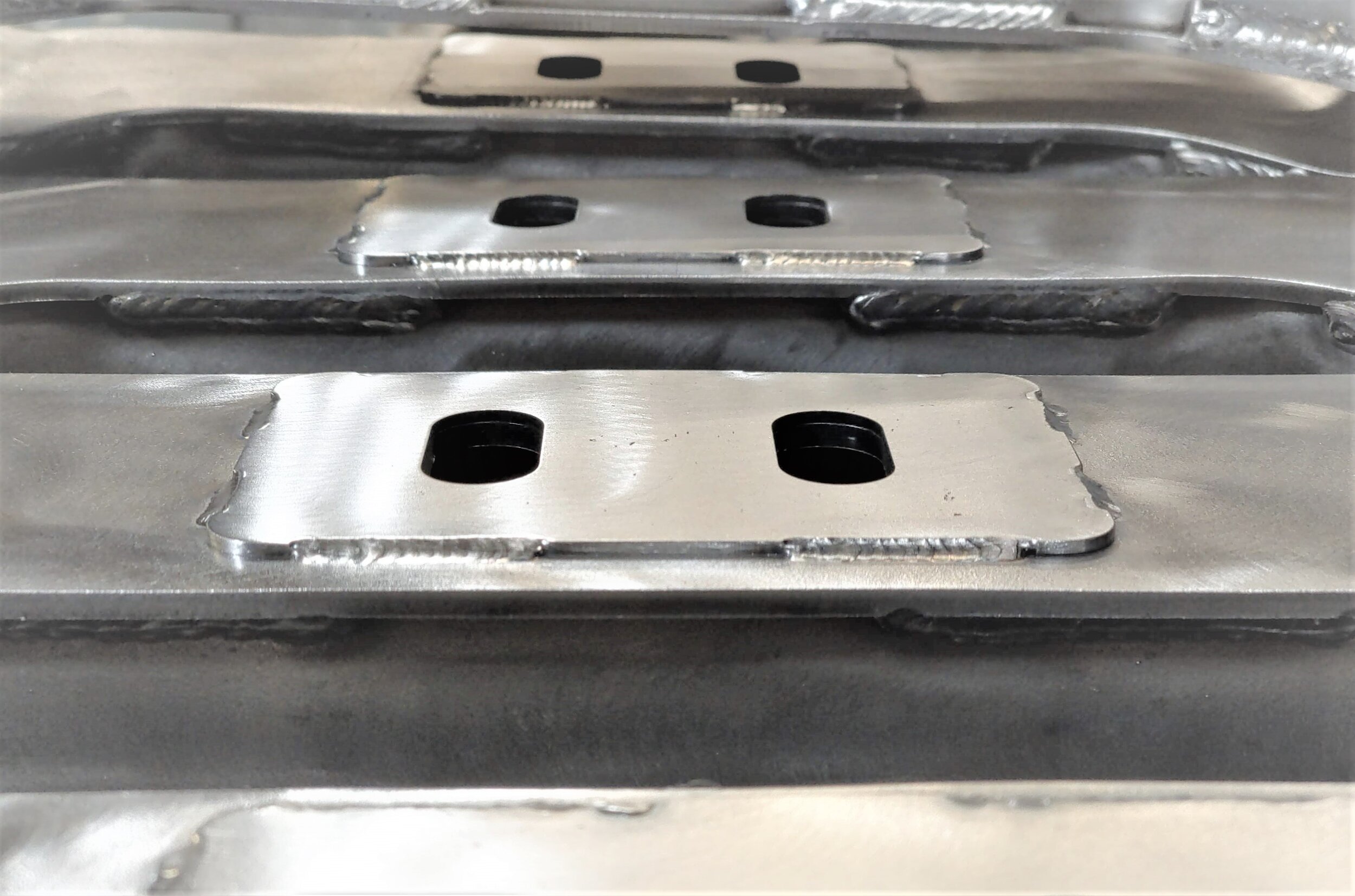

Welding

Mig welding

With four fully equipped hand-welding MIG workcenters and one spot welding machine, our fabrication team has the equipment, experience, and skill to get the job done, even under the most strict guidelines for weld callouts.

tig welding

We use multiple hand-welding TIG machines to get jobs done which MIG can’t do, or isn’t as well suited for.

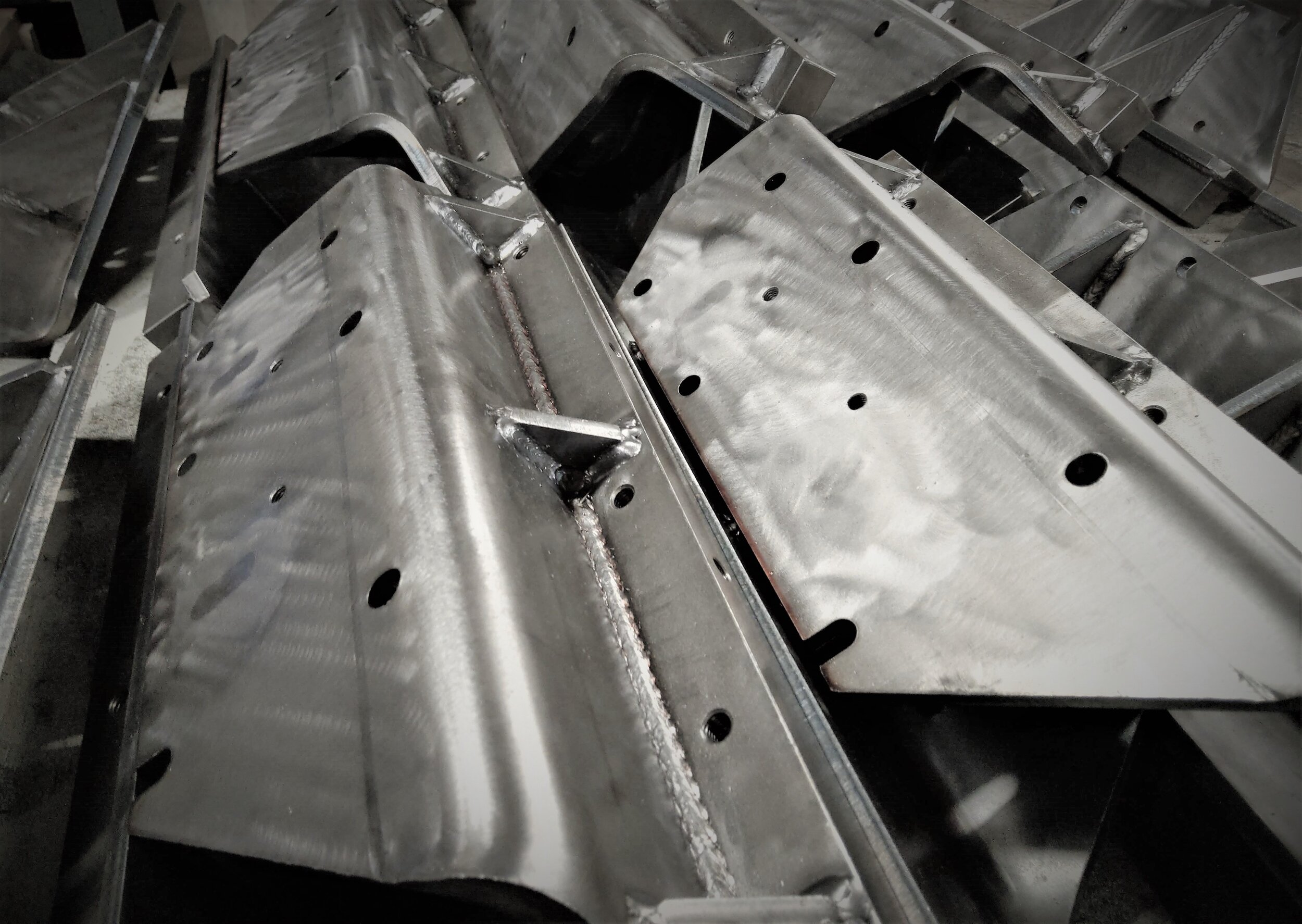

robotic welding

Our robot welding machines have standardized form factors proprietary to FMP from which we can easily fabricate and test fixtures for use in higher volume weldments at lower costs and better consistency than hand welding. This cost savings is passed down to customers during the quoting process.

Machining

CNC Milling

With the addition of our new VF7 HAAS (seen above), milling has never been easier at First Metals. With a 28” x 84” work table that can support up to 4000 pounds, a 30 horsepower spindle, and a vertical 30 tool changer, this machine, purchased in 2018, has increased our capacity and and capabilities.

We have 3 other HAAS CNC milling machines which accommodate high accuracy, high speed, and versatility, as well as several other CNC and manual mills to maintain capacity and availability.

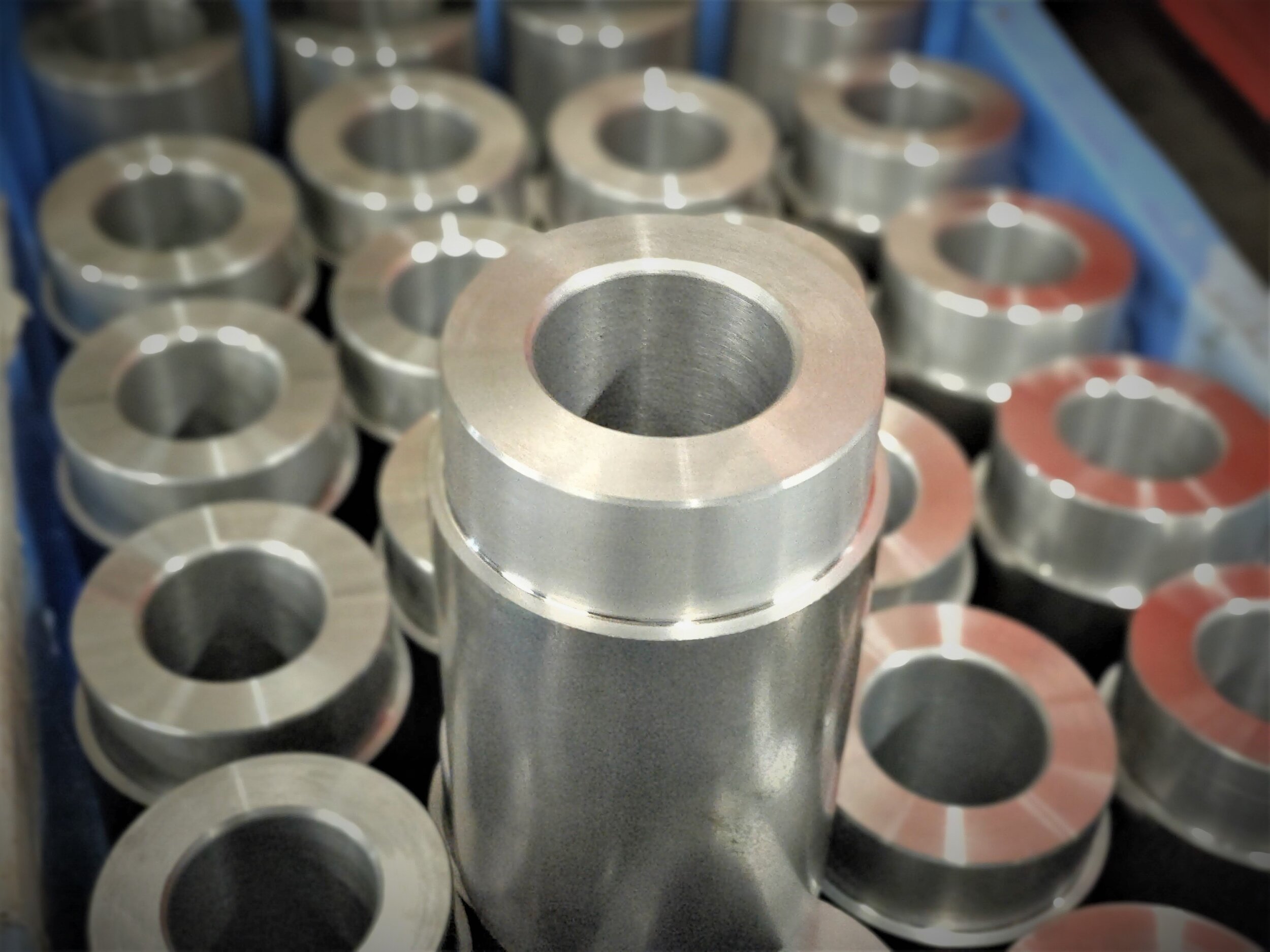

CNC Turning

We have a diverse selection of CNC lathing machines including brands like Fanuc, Okuma, and HAAS, which are capable of working up to 24 inches in width and 3 inches in through hole diameter.

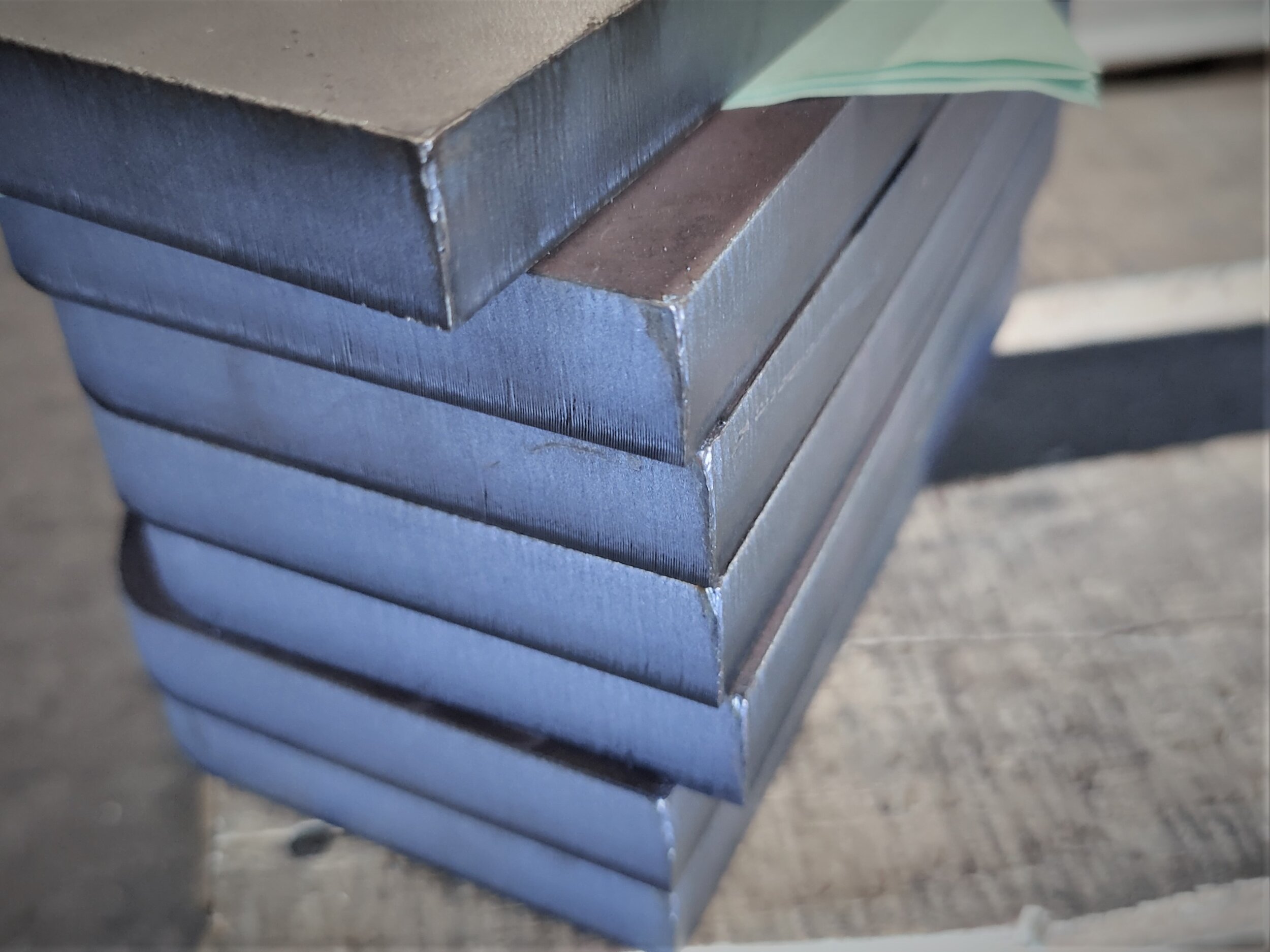

blanchard grinding

We can grind to within +/-.001 inches on our in-house Blanchard Grinder, which supports work pieces up to 36 inches in diameter by 18 inches tall.

Broaching

We have the capabilities to do both vertical and horizontal broaching.

stamping

Die presses

First Metals has over 20 Stamping Presses, ranging in size from 22 tons to 1000 tons. We can accommodate steel coils up to 10,000 pounds. We welcome both small lots as well as continuously running jobs. The press rooms have a full complement of feeding equipment. Coil width up to 24 inches can be processed and thickness up to ¼ of an inch can be fed from coil.

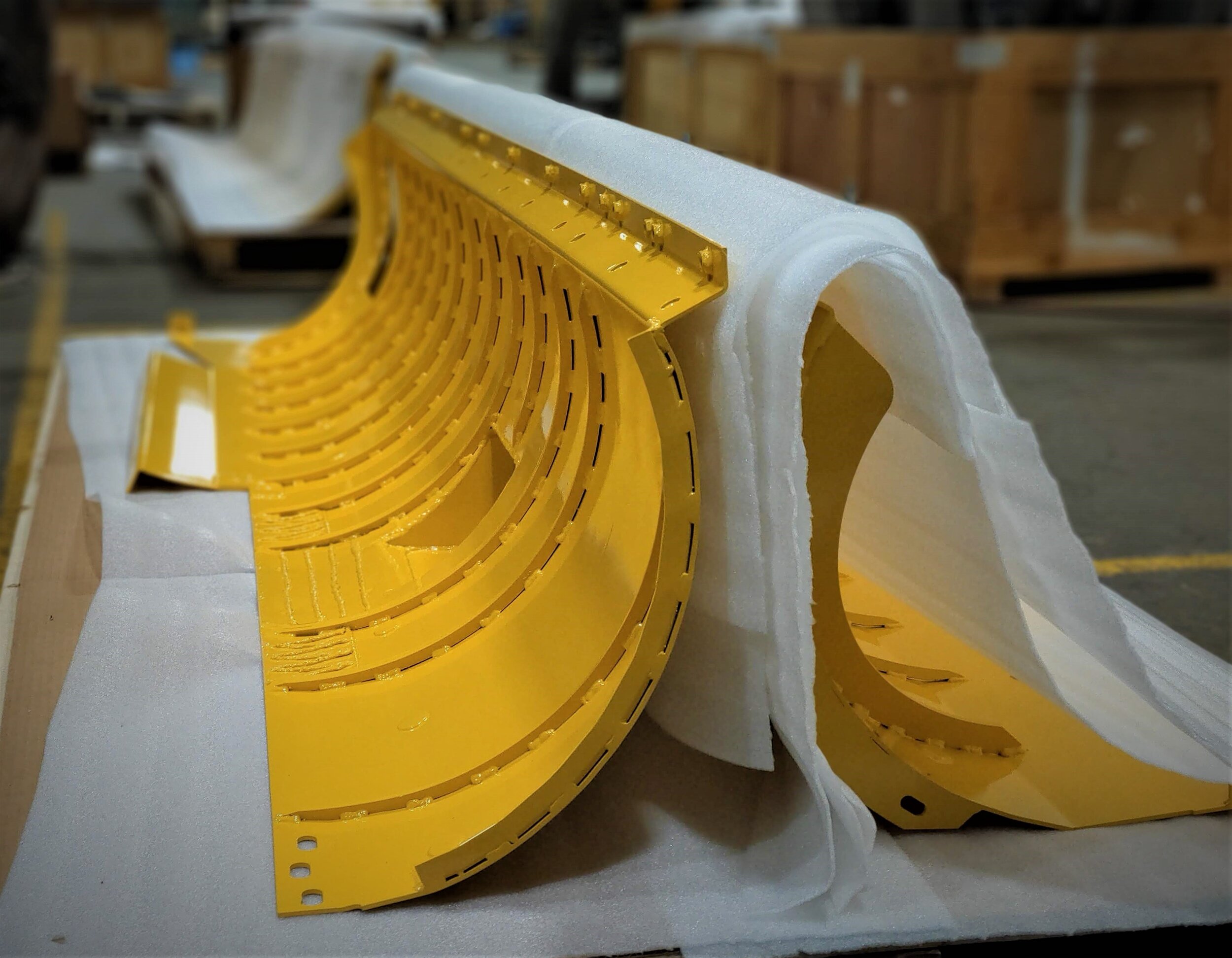

Hot Forming

Though hot forming steel is highly specialized work, here at First Metals, we have everything we need to get the job done including a 20 foot conveyor oven and induction heater, presses up to 1000 tons, and the equipment and expertise needed for custom die-making. Our planning and production team will work with you to meet your needs.

Painting

With our commercial paint line, we can spray industrial paint coatings onto a wide range of materials in a great variety of sizes. With 2 paint booths and a conveyor-fed paint oven, our team of industrial painters can accommodate most paint needs in house, only leaving a few specialized jobs to be sent out to our partners for coatings such as zinc, anodize, and powder coat.

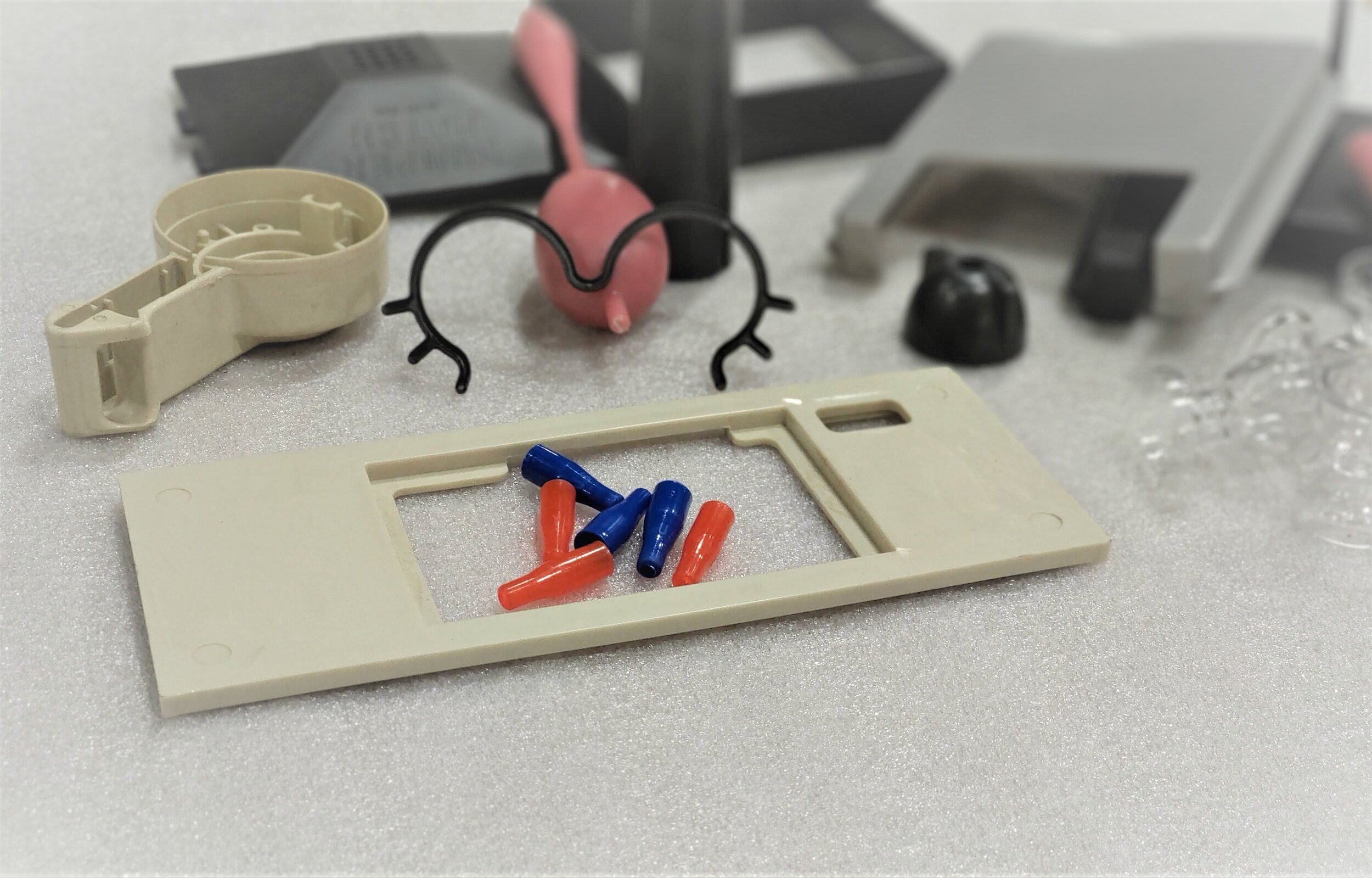

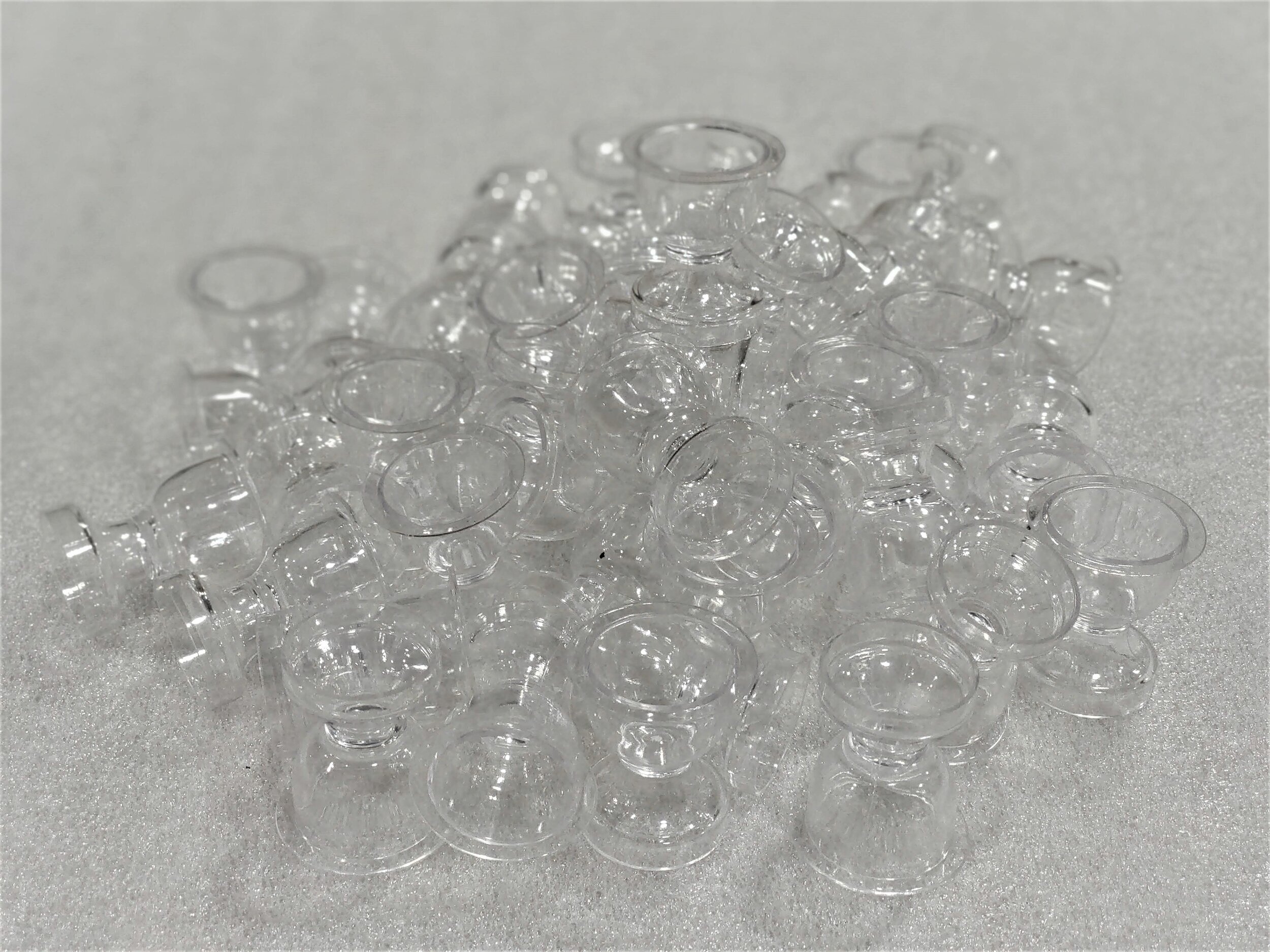

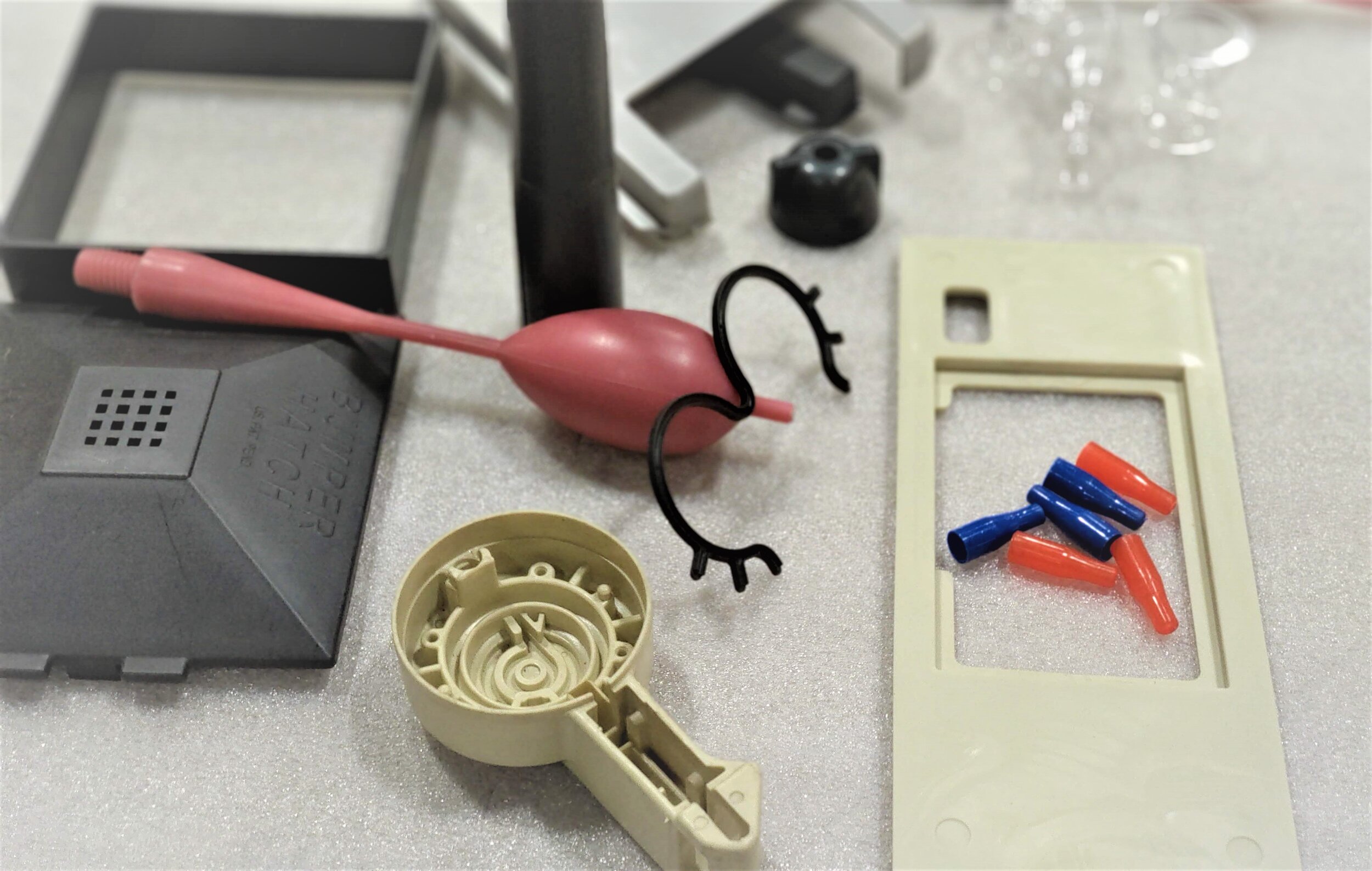

injection molding

Plastic injection molding

The injection molding department is equipped with machines from 75 to 1000 tons. An assortment of hot stamping presses, color feeders, conveyors, chillers, more are available to support your molding needs. Platinum sizes up to 60 x 60 and 160 oz. We are capable of assembly and packaging at the presses.

Laser Marking

Our New Marking Laser is a 50 watt fiber laser by Tykma Electrox capable of creating a great variety of different marks, such as burn marking, anneal marking, deep engraving, etc.; on an even greater variety of materials such as steel, stainless steel, and aluminum, various plastics, some wood, paint and other coatings such as anodizing. We can put a mark on just about anything, and the mark we make is up to you. We can use any font, mark any number, letter, symbol, or shape, from part numbers to company logos, plaques, or even photos. First Metals will work with you for all your engraving needs, including large parts other companies aren’t equipped to handle.

Surface Finishing

Timesaver

“Timesaver” is the brand of wide belt, abrasive, finishing machine that we use for sanding steel, stainless steel, aluminum, and a wide range of other materials to provide either a brushed finish or as method of pre-processing parts before being painted, plated, anodized, or coated to help with consistency and adhesion of a finish.

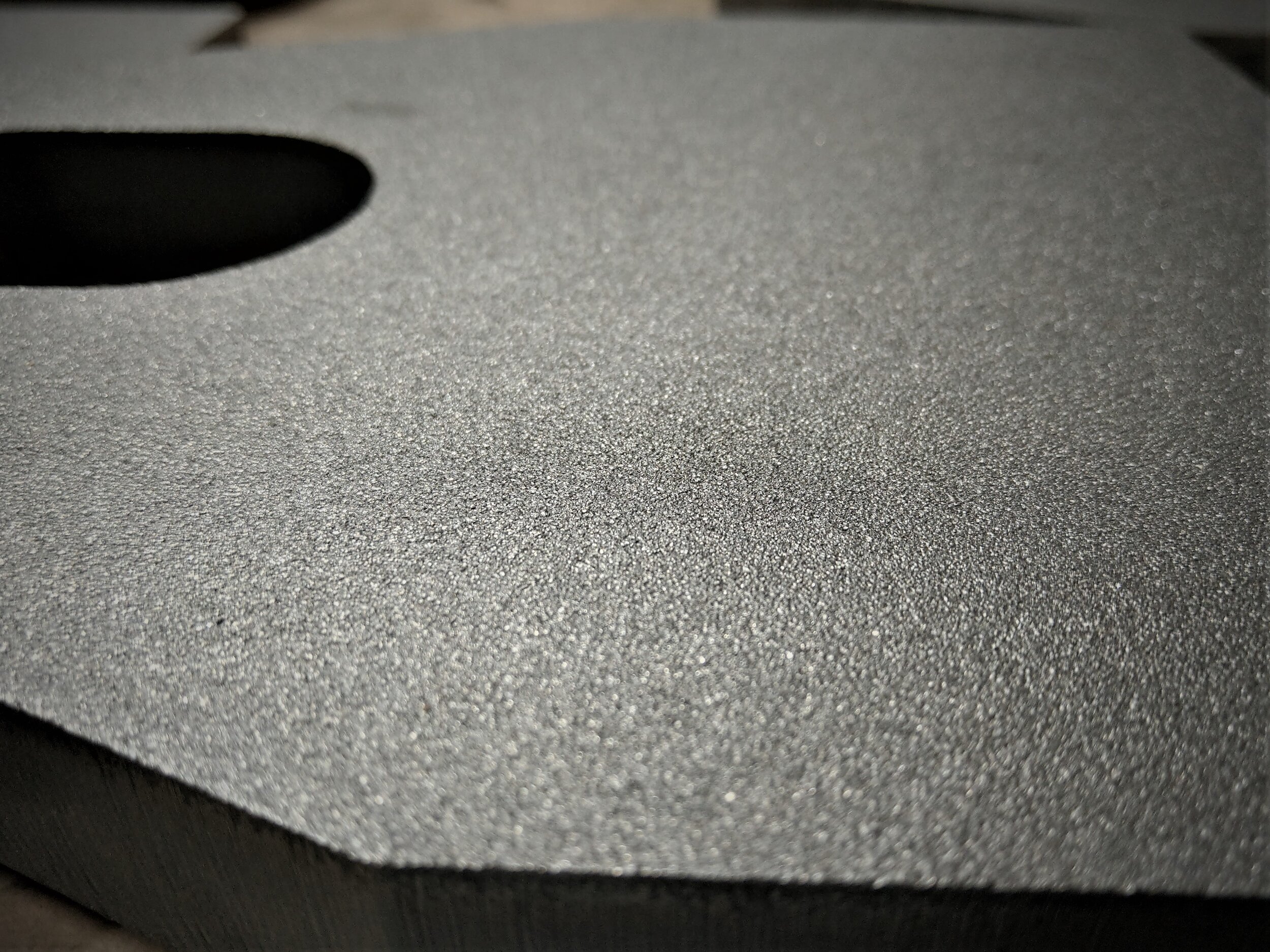

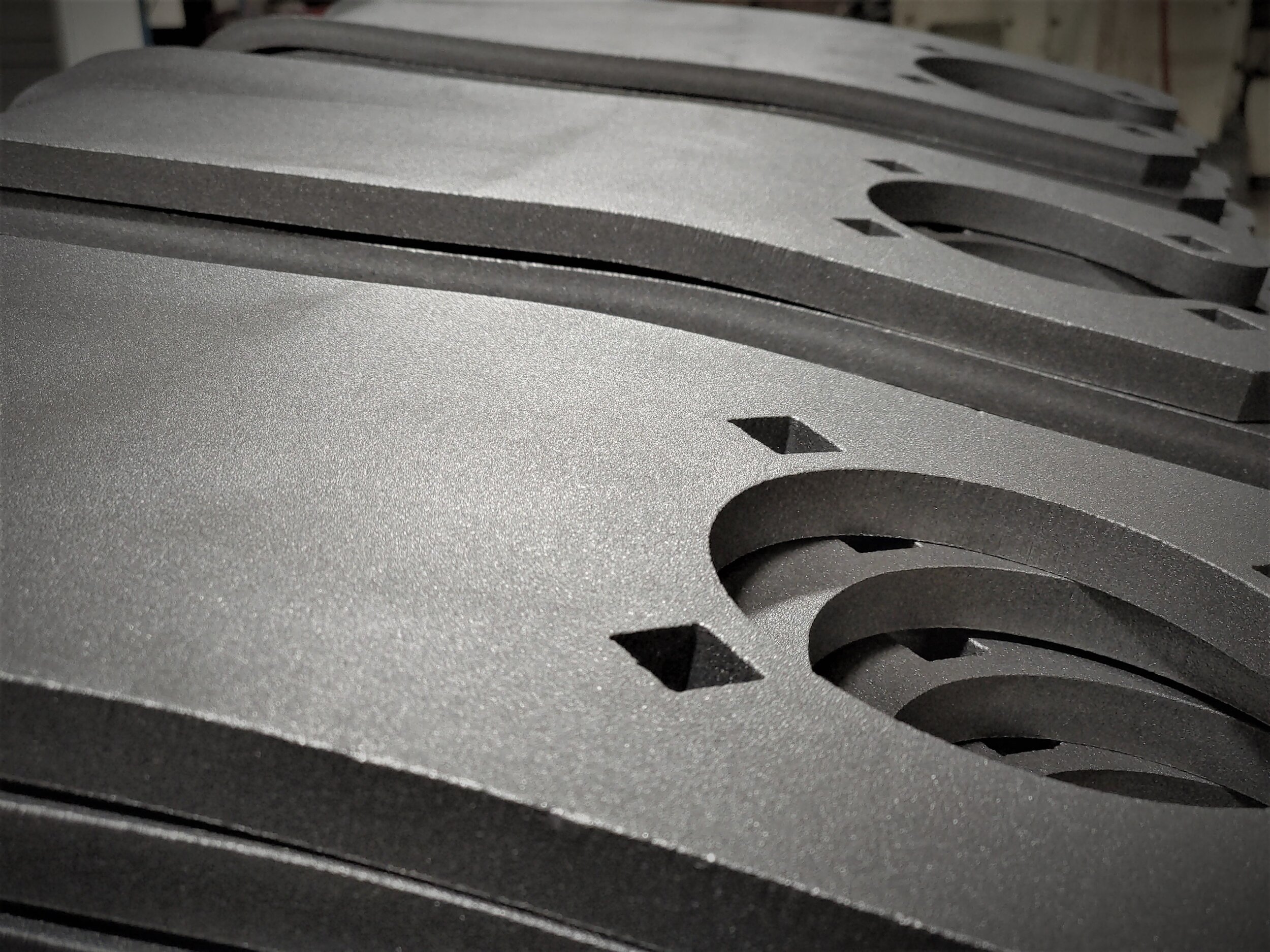

Shot Blasting

Similar to sand-blasting, shot-blasting just uses metal “shot,” much like a shotgun, to blast the surface of metal parts, leaving a somewhat peened and very consistent surface finish which is clean of paint, rust, residue, or most other coatings and ready for further surface finishing. We only shot-blast steel parts, as the shot, made of steel, will impregnate stainless or aluminum with steel traces which will rust or corrode over time.

Chrome Plating

We partner with specialists to offer hard chrome plating and polishing as required and upon request.

Zinc Plating

We partner with specialists to provide yellow, clear / bright, and black zinc plating as required and upon request.

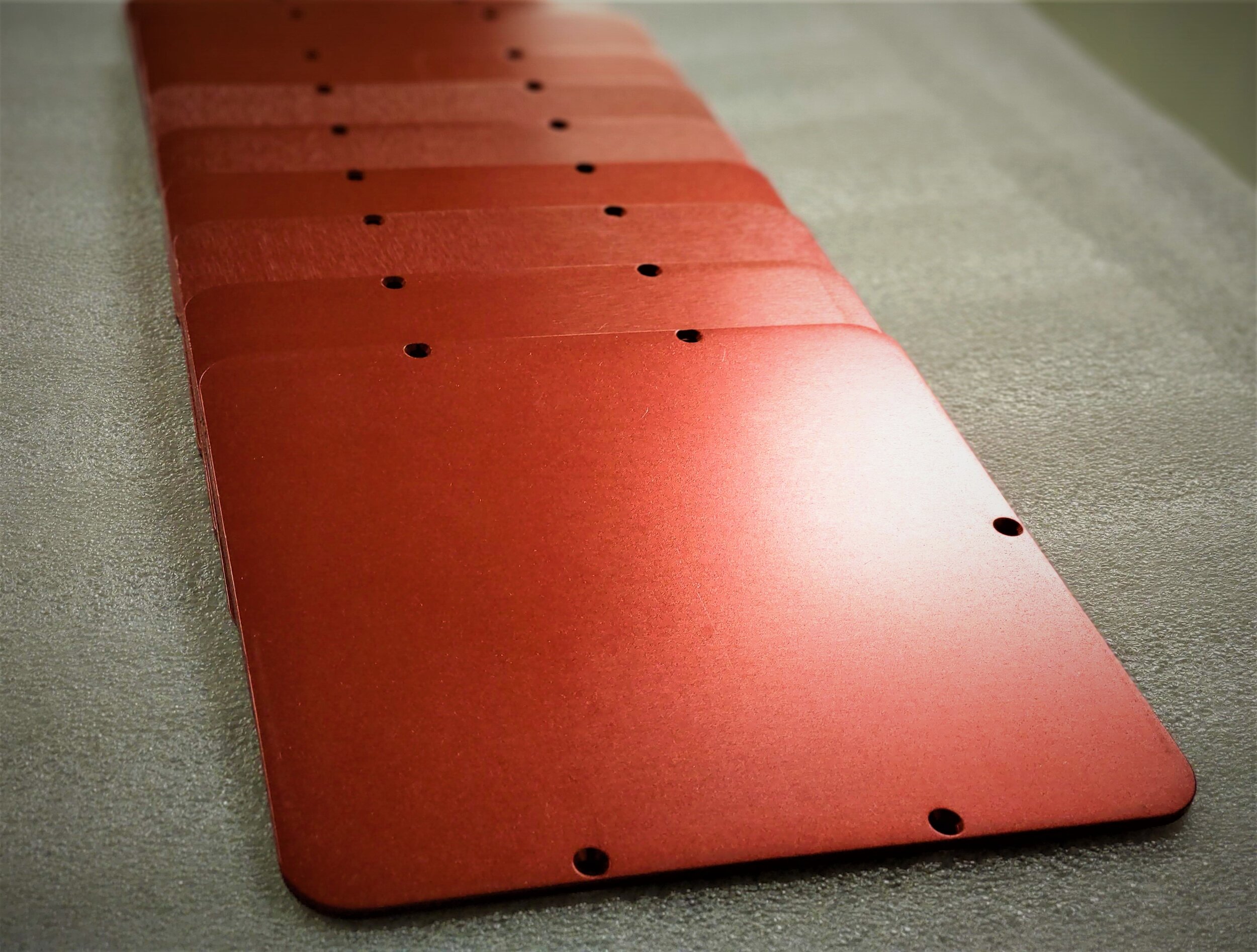

Anodizing

We partner with specialists to anodize aluminum in any color, and we can color match to your sample, if required and upon request.

Other Capabilities

Saw Cutting

We have a variety of saws to choose from in order to effectively and appropriately get the job done.

Iron Worker

Our iron worker makes short work of high volume blanking of common sized round bar, square bar, and angle iron.

TUMBLING and Vibrating

For a more uniform finish, our tumbling and vibrating machines can run unattended for as long as necessary to achieve the desired result.

rocklinizing

Our Rocklinizing Machine can impregnate blades with high-hardness tungsten carbide to reduce the frequency or need for sharpening.

heat treating

Our partners provide us with a large array of hardening capabilities.

Our partners can provide casting blanks for larger volumes of parts which are more economical to start as a casting than a fabricated part.